A diffractive hybrid lens can be made thinner than a conventional lens. Another advantage of hybrid DO’s is that the focal lengths at the minimum and maximum wavelengths can be set equal to each other in order to minimize chromatic aberrations. However, lens performance is limited to a narrower spectral band than would be the case with a conventional lens.

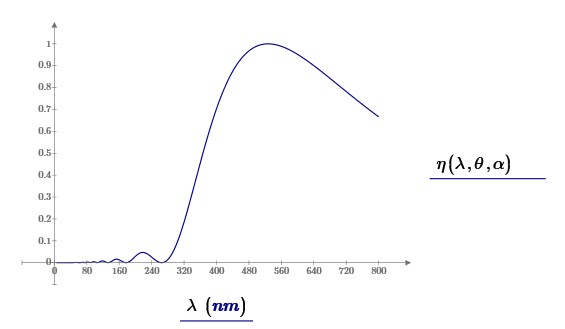

The dependence of scalar diffraction efficiency on wavelength is shown below for a lens I designed and had fabricated several years ago. Factors that went into deriving this curve include the design wavelength, design order, and diffraction zone width and depth. Note the dramatic falloff in efficiency, especially on the short wavelength side of the curve. Similar to a diffraction grating, when the efficiency at the design order falls below 100%, light is lost to unwanted diffracted orders, and becomes stray light.

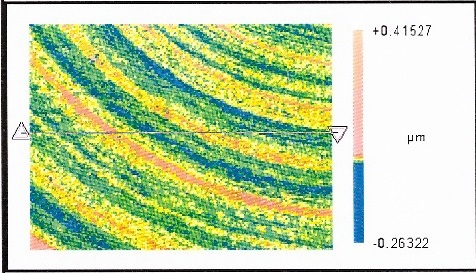

Scatter from the rough, diffractive surface contributes to stray light as well. This lens was diamond turned from a polymer. The zone topography is shown below.

Indeed, an aspheric doublet that I designed as a baseline lens for the same camera provided superior resolution and contrast for our full-color scenes, although at twice the weight and thickness.

One way to achieve high diffraction efficiency over the entire visible band with minimal flare is to stack multiple diffractive layers, as has been done for decades in the design of compact, high-end zoom lenses. This approach can also reduce sensitivity to ray angle-of-incidence.